Comparison of coolers using heatpipes

Fire, water and brass horns

As you can guess from the title, today we are going to cool today's hottest processors ("Fire"). That is surely Pentium4, which has a heating power of 100W. And this value can increase after new processors on new Prescott kernel are issued. It is clear that standard aluminum coolers are absolutely ineffective for this. That is why manufacturers are searching alternative methods of cooling, two of which are examined in this review. The first one is Poseidon, the system of liquid cooling; and the second is using of heatpipes (brass horns).

A couple of words about heatpipes. The main goal of a heatpipe is to conduct heat from one end to another. Generally, heatpipes are made of brass and contain easily-boiling liquid. Inside a pipe (from the side of the source of heat) the liquid evaporates and absorbs heat. At the opposite end, the liquid condenses if a radiator is applied to the pipe. In other words heatpipe is used for heat conduction and cannot cool a processor (or other heat source) itself. By the way, we have already reviewed similar cooling systems; these are videocard coolers Zalman ZM80C-HP.

Thermalright SP-94

Taiwan company Thermalright has a very interesting approach to business: it sells only heatsinks. That is a user must install fan himself according to his own taste. The heatsink is supplied in a big cardboard box.

It must be noted that all the components are thoroughly packed in foam-rudder to prevent possible damage during transportation.

Besides the heatsink itself, the package contains a bracket, a slab and a syringe with thermal paste and a bracket for a fan. First of all we will look at heatsink design.

So on a brass base there are more than twenty brass ribs. For faster heat conduction, three heatpipes are built in heatsink's base.

Because of that, each rib touches a pipe with rather big area. In order to achieve this effect, each rib has special petals, which fold a pipe. Besides that, between a pipe and a petal, there is a thin coat of thermal interface, which also improves heat conduction.

Contact between ribs and heatsink base is made with the same quality. Each rib is inserted into a special slot in the base. Besides that, ribs have small platforms, which touch upper side of the base. Thermal interface is actively used here.

As the result we can make the following conclusion. Although ribs and basement are not monolithic, the effectiveness of SP-94 heatsink does not concede the effectiveness of monolithic heatsinks.

Concerning the base, its quality is very, very good. Like on the majority of good coolers, there is a protective film on the base, which is removed just before the installation of the eatsink. By the way, installation of the heatsink is a time-consuming process and an ordinary user can consider it difficult. Especially if we take into account the lack of an installation manual in the package as well as on the company's site.

However this product is designed for overclockers and similar "advanced" people, which can do it themselves. So the first step is the removal of attaching frame from the motherboard. To do this we are taking out plastic pins and then remove the frame with pliers (or with strong fingers).

Our next step is the installation of the plate. In the center of this plate there is a rubber backing, which prevents short circuit. For this we are passing special pins through holes of the motherboard and tighten them. It is not necessary to tighten strongly, several turns is enough.

One can optionally put plastic insertions under hobs. The package contains them. In the next step we are salving thermal paste (I used KPT-8) installing the heatsink and looking at the imprinting.

If all pins are tightened evenly, the processor imprints completely.

Then everything is simple: we are inserting springed bolts and screw them chock-a-block.

There are extra details after the installation, but don't worry, they are spare.

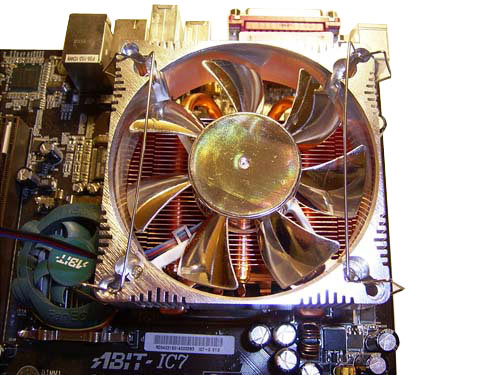

The next step is installation of a fan. For this we are taking an appropriate fan and fix it with the wire frame.

92mm fan Titan

92mm fan Titan

It is allowed to install 80mm and 92mm fans onto SP-94 heatsink. Which fan must be installed: noisy and productive or quiet is the user's responsibility. I used 92mm Zalman ZM-F2 fan with ~2800RPM rotation speed and ~36dB noise level for testing.

The preliminary conclusion is that SP-94 heatsink appears to be good and effective product, which will interest mostly overclockers. Installation procedure seems quite simple (it is not necessary to think much), but rather time-consuming.

Next

|

Content: |

|

|

|

Top Stories: |

|

|

|

MoBo:

|

|

|

|

VGA Card:

|

|

|

|

CPU & Memory:

|

|

|