All you need to know about your products!

| 3DNews Vendor Reference English Resource - All you need to know about your products! |

||||||

|

||||||

|

|

||||||

In 2004/2005, the battle among the manufacturers of processors and cooling devices came up with a bang. Intel released new processors whose heat emission was too much even for "boxed" coolers. The other competitors started desperately developing coolers having huge radiators and/or heat pipes. Complication of the design ended up in the appropriate result: coolers turned more expensive. Some models have already exceeded the 50$ bar and are coming close to 60$. It's not possible to raise the price further: with 90$-100$ you can already buy a water-cooled system (some manufacturers are already promising to produce a water-cooled system at 30$ - for details, read the coverage of Cebit 2005).

Somehow or other, we got the impression that even with the use of heat pipes the efficiency of air-cooled systems has approached its technology limit. It's no longer possible to further improve the products without raising the cost.

From the viewpoint of the regular user, the crisis of development for air-cooled systems is also evident. Because no cooler is able providing a reliable cooling to a high-end processor in the noiseless mode (or close to that). That the CPU unit howling like a vacuum cleaner is presented like a triumph of advanced technologies is again another evidence of weakness of coolers manufacturers (or the conceptually wrong progress of CPU architecture.

If we look at the cooling devices from the overclocker's perspective, they have no other alternative but to switch to water-cooled systems. That is because almost all the latest Prescott processors for LGA775 socket can easily get over the 4GHz bar with 130-150 W power consumption. However insane (in good sense) the overclockers are, they also want noiseless operation of the CPU unit. From this viewpoint, none of the products tested today satisfies the requirements of overclocking fanciers.

There is one fine point, though: to produce high results, many manufacturers of coolers use quite noisy (but powerful) fans. As a result, on the temperature graphs we see values at about 50-55C which points to some margin for the processor's clock speed (remember that the emergency mode Throttling is enabled at about 70C). However, the noise of the cooler running at maximum RPMs resembles the rumbling of airplane and its use is allowed for a short time only (without detriment to the hearing).

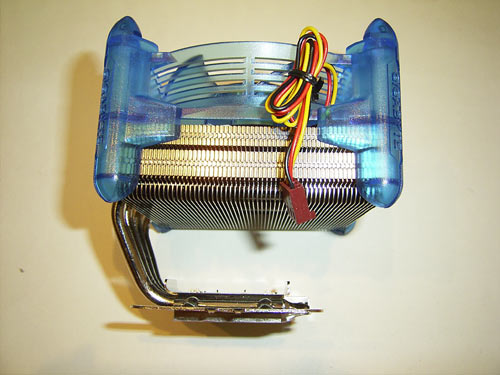

Gigabyte continues expanding its line of cooling devices. Following the quite successful 3D series of coolers, this manufacturer presented an entirely new model - G-Power - for the public judgment. Its design is rather unusual, and well-proven heat pipes are used in it:

The cooler is shipped in a big plastic box with a transparent window.

Inside the box, we found the following components:

The exterior of the cooler is impressive enough: from the aluminum base, there emerge four heat pipes which are mounted into a big aluminum radiator.

Right on the radiator, there is a 110 mm fan with a housing of blue plastic. On the frame, there are four blue LEDs which provide effective illumination while the cooler is running.

With the regulator, the user can adjust the fan's rotational speed within the range from 1700 to 3200 RPMs. At the same time, the noise level varies within 21 dBa to 45 dBa, with the air flow fluctuating within 36.2 CFM to 68.5 CFM.

The overall mass of the cooler is 430 g, which is relatively not much. The small weight of the cooler as well as its reliable fastening to the socket allow safely carrying the cooler around.

Take a close look at the base whose rear side is of quite intricate shape. That is made in order to provide a complete universality of the cooler. In particular, Gigabyte G-Power is compatible to all popular platforms: Socket478, Socket939, SocketA (Socket462), and SocketT (LGA775). To install the first three types of motherboards, various clips are used, and to fasten the cooler on a socket LGA775 motherboard a plastic fastening frame first has to be fitted (the design of the frame is completely similar to the frames used to install 3D Cooler series).

Installation of the cooler on motherboards is not an issue at all. If the user is not experienced, the user guide comes in handy, which contains a great number of illustrations, with the text presented in nine languages.

As regards the processing quality of the base, it is satisfactory:

The cooler is equipped with a speed regulator unit, to which either a regulator into the 3" panel or a regulator on the bracket can be plugged in (the bracket is installed instead of one of the expansion cards).

Of special mention is the very low noise level at the minimum speed. At this parameter, Gigabyte G-Power could be on par with Zalman produce. But if you put a hand to the radiator, you can feel quite an essential vibration, which points to the middling quality of the fan balancing (i.e. Gigabyte could have made the cooler much quieter). At the maximum RPMs, the cooler noise is quite tolerable, and at middle RPMs quite comfortable operation is possible.

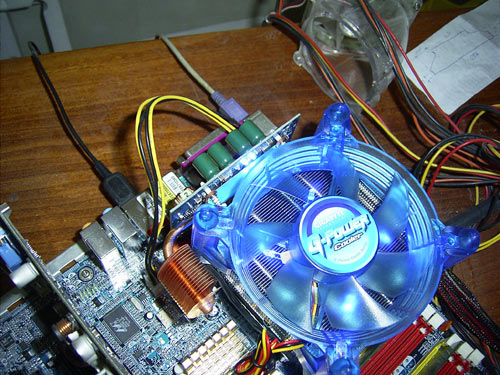

In conclusion, let me bring in a photo of the G-Power cooler installed on Gigabyte 8AENXP-D (i925XE) motherboard:

By the way, installation of the DPS module causes no issues:

Pros:

Cons:

P.S. Along with traditional air-cooled devices, Gigabyte plans to release its own water-cooled system. It was first exposed at Cebit, and at the June's Computex a complete product was demonstrated.

At first glance, the ThermalTake Jungle525 AE cooler is a hypertrophied replica of a boxed cooler.

In particular, the dimensions of the radiator and fan have been increased, with the shape of the latter somehow changed:

Technical specifications of the fan are as follows: dimensions - 90x90x25 mm, rotational speed - from 600 to 3700RPM, air flow within 10.3 to 63.51 CFM, noise level from 15 to 46.5 dBa.

Upon the copper base of the cooler there is a pre-applied layer of thermo paste which is protected by a large plastic lid.

Thus, there is a guarantee that on transportation the layer of thermo interface will not get smeared over the box. By the way, the box with the cooler looks like this:

There is nothing else inside but the cooler itself. The processing quality of the base is decent enough (although grinding traces are visible).

The very first start-up of the cooler was deafening: at the maximum speed, no comfortable work at the computer is possible. And we can't forcedly reduce the rotational speed - the fan has a 4-pin connector. As a result, reduction of the rotational speed is possible through the motherboard's features only. In fact, I don't think the user will ever have the need to reduce the rotational speed - even at the maximum speed the cooler fails to cope with cooling the Pentium4 660, and stable operation of the system under load is possible only due to the features in charge of protection against overheating embedded into the processor (Throttling and Thermal Monitoring 2).

Another problem of the cooler is in the design of the radiator: power air flow is simply reflected from the fan and directed upwards. That is easy to detect if you put your hand closer above the cooler.

Pros:

Cons:

Scythe, a Japanese company little known on the Russian market, has presented a number of unusual and interesting products.

The first cooler - Kamaboko - offers quite a standard design: a massive aluminum radiator with a copper insert in the base and a large 92 mm fan.

The cooler is packaged in a stylish box with a transparent plastic window.

Apart from the cooler itself, in the box you can find a set of fasteners suitable for all the popular platforms (Intel LGA775, Socket 478, AMD Socket754, and Socket939).

There is also an instruction guide to the cooler (in English and Japanese languages) which describes the set-up procedure.

The main feature of the cooler - it is a rather quiet (22.9 dBa) and powerful (47.3 CFM) fan. At the same time, the maximum rotational speed is 1900RPM.

The fan is equipped with a 3-pin power connector and is attached to the radiator with wire clips. The radiator itself did not leave a strong impression because of the sparse, thick and low-set fins.

The radiator base is a copper plate with the surface processed well enough:

Installation of the cooler on a LGA775 board is quite a hard task which takes much time. The major problem is fastening of metal plates with "hangers".

To do the operation, the following has to be done simultaneously: hold the motherboard, hold the metal enforcement plate (thus aligning the holes with the assembly holes on the board), hold the plate with hangers on the other side of the board (again aligning the holes), run the screw through and tighten it with a screwdriver. In other words, this task is not for a regular user but a juggler :).

Lastly, when the plates with "hangers" are in place, you should snap the fasteners on the cooler. At first glance, the task seems simple - just press the latches until the last ones run through the "hangers". But the fasteners are so tight that the strength of Schwarzenegger is needed to handle them. To be more precise, a couple of Schwarzeneggers is needed because it is advisable not to warp the cooler during installation.

Finally, on some boards the radiator may rest against onboard components (e.g. the way it is on the photo of Asus P5AD2-E).

Pros:

Cons:

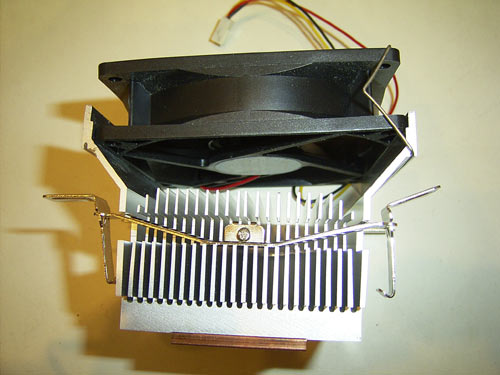

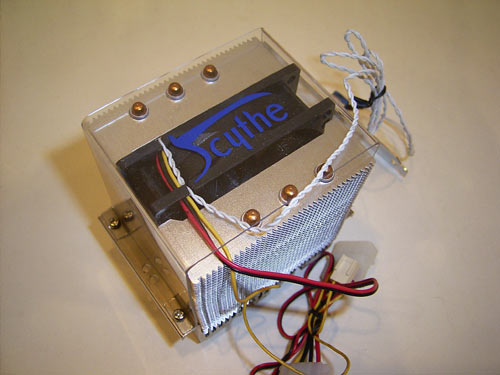

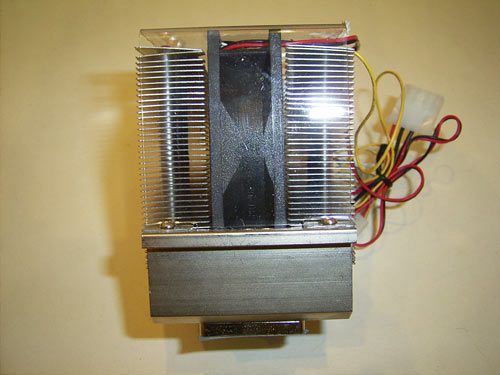

The next cooler is dubbed Samurai, and we received its improved model (rev. B).

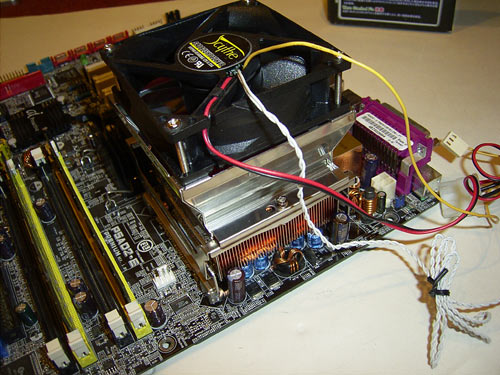

On the cooler, there is a 80 mm fan of variable rotational speed. The variation range is between 1300 RPM to 4600 RPM. At the same time, the cooler noise varies within 15.1 dBa to 46.1 dBa, and the air flow within 15.2 CFM to 60.6 CFM.

Control of the rotational speed is effected with a regulator fitted on a special bracket. The fan is powered through a 4-pin Molex connector.

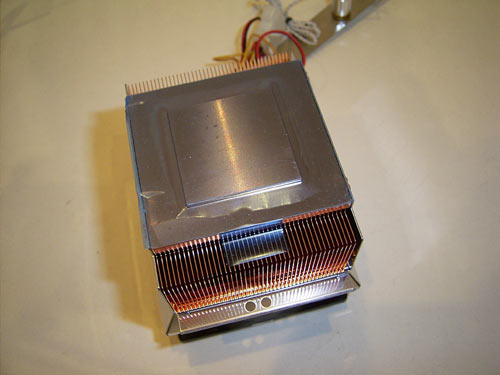

Half face, the radiator looks like this.

Note that although the radiator is made of copper, it has some engineering shortcomings. In particular, the fins are glued to the base. That naturally reduced the radiator's efficiency as compared to those full copper. The base of the radiator has excellent processing quality:

to provide protection against scratches, it is covered with a special film (prior to installation on the cooler, it has to be removed).

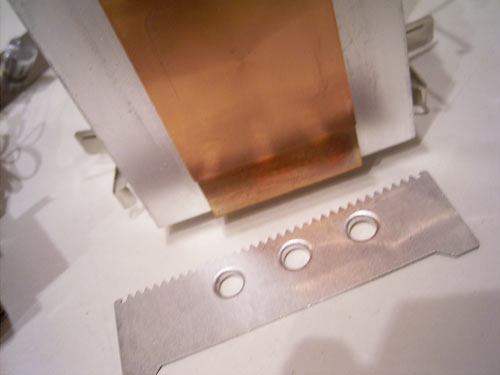

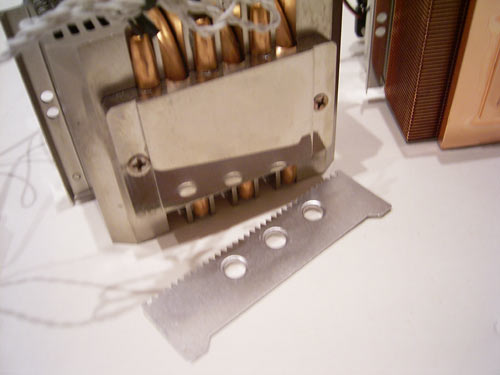

Installation of the cooler is almost the same as in Kamaboko cooler. The only difference is that a metal plate to which the cooler is screwed is fitted on plates with hangers.

Pros:

Cons:

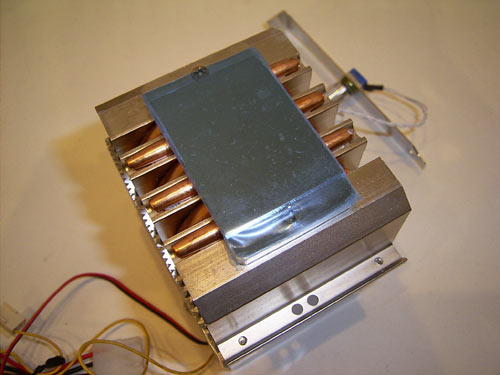

The last of the examined coolers is called Kamakiri and is the most practically feasible.

The package of the cooler is the same as in the previous Scythe products, with the package bundle matching that of the Samurai model. The installation procedure is precisely coincident.

For that cooler the engineers of the Japanese company used the same fan as is installed on Samurai cooler. The variation range is between 1300 RPM to 4600 RPM. At the same time, the cooler noise varies within 15.1 dBa to 46.1 dBa, and the air flow within 15.2 CFM to 60.6 CFM. Also unchanged is the speed regulator positioned on the bracket.

The most interesting component of the cooler is its radiator which is an aluminum base on which there are 6 heat pipes. On each three pipes a great number of aluminum plates is strung.

Over the sides and on top, the radiator is covered with a plastic housing. It acts as a conductor pipe through which air is fed. Thus the housing makes the air-flow work more efficiently. Note that the fan's efficiency is very high. The incoming air flow also serves to spread heat from half the fins of the radiator.

However, the radiator offers its shortcomings. In particular, each radiator fin has quite a poor contact with the heat pipe, without any signs of soldering or a binding thermo interface. Therefore, the plates are easy to remove without any tools.

The processing quality of the base is very high:

To provide protection against scratches, the same transparent film is used:

On the whole, of all the above listed coolers by Scythe, we liked the Kamakiri cooler most. Its cooling efficiency outweighed the shortcomings like complicacy of installation and large overall dimensions.

The cooler's overall dimensions are 99.5x72x110 mm, but the total weight of the cooler (together with the fastening) does not exceed 700 g (to be precise, 675 g).

Pros:

Cons:

Glacialtech has presented a new line of coolers - Igloo 5070 and 5050 which is aimed at Intel LGA775 processors.

Like most coolers made by this company, the Igloo 5070 series offer one type of radiator and a number of fans with various specifications.

In particular, the generic model offers a 90 mm fan of rotational speed 2800RPM, noise level 32dBa and generates 46.50CFM air flow. The Light model is aimed at those who want quietness, and thus the fan runs at the reduced speed - 2400RPM. The air flow generated amounts to 39.80 CFM, with the noise level not exceeding 28 dBA. On the contrary, Igloo 5070 PWM is positioned as a solution for computer enthusiasts. That is why the fan runs at speeds within 800RPM to 3800RPM, which allows generating air flow within 13.30 CFM to 63.10 CFM. Therefore, the noise level varies within 18.0 dBa to 40.0 dBa. Note that the latter cooler does not offer a speed regulator. But, unlike the models 5070 and 5070 Light, it is equipped with a 4-pin power connector. This allows adjusting the rotational speed with the motherboard's features.

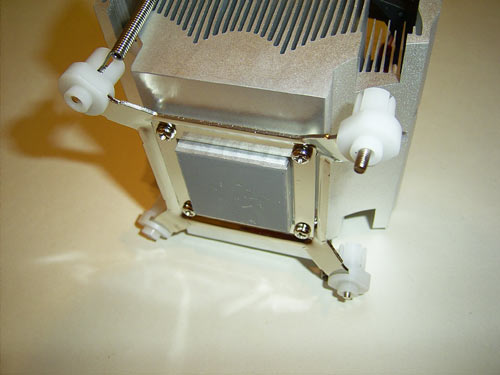

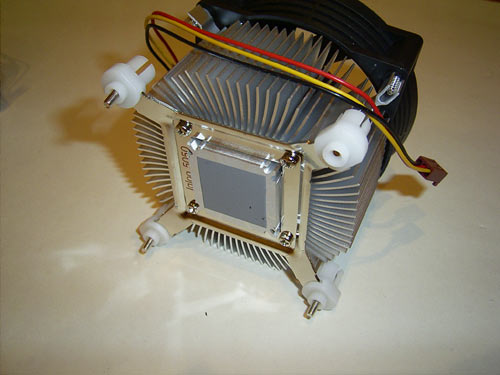

The cooler's package is quite commonplace - a white cardboard box. Inside, apart from the cooler, we found an enforcement plate on the board's reverse side.

Note that this plate is fully made of metal, and to prevent the contacts from closing it is separated from the board with a rubberized washer with a gluing substrate. The glue is so sticky that after the laborious removal of the plate residues of the washer are still there on the motherboard.

On the whole, the procedure of cooler installation is easy enough and is much easier than installation of a boxed cooler. First of all, the enforcement plate has to be glued, then there goes the cooler and then tighten the screws uniformly.

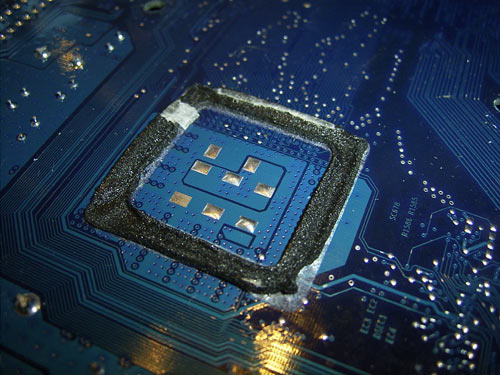

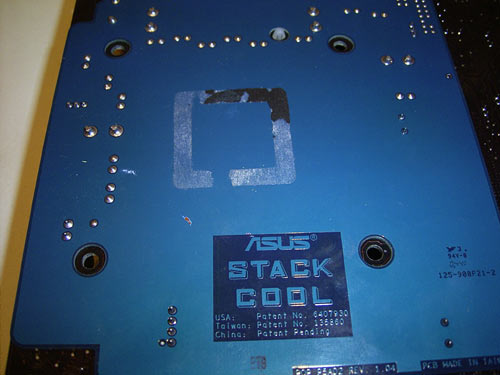

Despite the ease of installation, you have to mess around with the cooler for quite a long time. Besides, there are certain issues of compatibility to some motherboard models. In particular, many Asus motherboards (e.g., a test specimen of P5AD2-E Premium) offer a system for cooling the power supply module - Stack Cool. Its component part is an aluminum plate on the reverse side of the board:

As a result, the fastening screws of the Igloo cooler partially don't reach the enforcement plate, so the cooler is not firmly pressed to the processor.

The radiator of Igloo 5070 series offers quite an intricate shaped base as well as great number of fins of various height.

On the aluminum radiator, there are is a fan attached with wired spring-loaded clips and two screws. As regards the cooler base, it is also made of aluminum. A layer of thermal interface is pre-applied to it, which is protected with a plastic lid.

Note that each cooler of 5070 series weighs 551 g. Coolers 5070 and 5070 Light are aimed at installation on Pentium4 processors of clock speeds not exceeding 3.4GHz and maximum heat emission level no more than 84W. The more powerful cooler 5070 PWM is therefore aimed at more powerful processors of clock speeds up to 3.8 GHz and heat emission up to 115W. These requirements are given without any "margin of safety", so should be strictly followed.

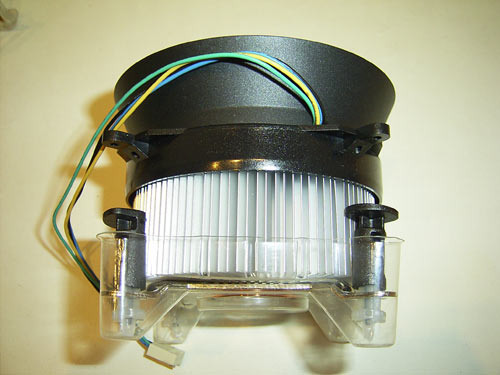

As regards the Igloo 5050 cooler, it is a boxed cooler, by and large.

The shape of the radiator is coincident with that for Intel coolers.

The differences are about the shape and characteristics of the fan. On the 5050 model, there is a 90 mm fan of rotational speed 2800RPM, generated air flow 46.50CFM, and the noise level = 32.0 dBA.

The base of the cooler offers the same layer of thermo interface (again, it is protected with a plastic lid). The procedure of installation and removal of the cooler matches that for a boxed cooler.

It should be noted that the Igloo 5050 series includes two more models: 5050 Light and 5050 PWM. Although we haven't received them for tests, let's bring in the specifications of the fans. On the Light model, there is a cooler of 2400 RPM rotational speed, generated air flow 39.80 CFM, and noise level 28.0 dBA. The specifications of the fan of 5050 PWM cooler are as follows: 800RPM - 3800RPM, 13.30CFM - 63.10CFM, and 18.0dBA - 40.0dBA. That is, if you have some spare time, you could remove the fans from coolers of 5070 series and test the coolers 5050 Light and 5050 PWM series at home by simply changing the fans. As you may have guessed, the design of the radiators of series 5050 is the same.

The pros and cons of all the coolers of Igloo 5070 and 5050 series are almost matching, so we have summarized them all into a table:

Pros:

Cons:

To check the efficiency of coolers, we assembled a test configuration based on Pentium4 660 (Prescott 2M, stepping N0). For that, the clock speed 3.6 GHz is too high and we decided not to subject the processor to overclocking.

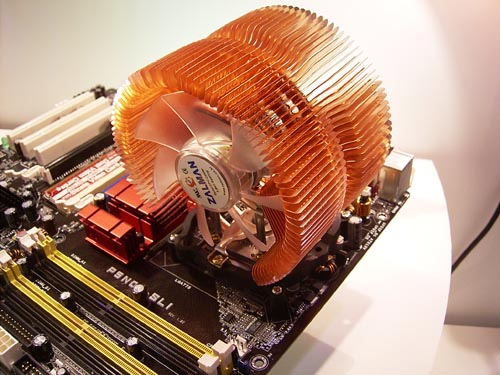

As the contender we used the "boxed" copper-made Gigabyte 3D Cooler and Zalman 7700Cu coolers. We also used the Gigabyte 8AENXP-D (i925XE) motherboard. We have to admit it took much of our time and effort installing the Zalman 7700Cu cooler. The thing is the installation was impeded by two huge "bulbs" of solder on the reverse side of the motherboard, so we had to work the motherboard with a file and the cooler was successfully installed :)).

To heat up the processor, we used BurnP6 run in two instances. As the thermo interface we used the very popular KPT-8 thermo paste (out of the tub :). So, here are the following results:

The first what we note is that starting from t = 66С there snaps on the internal protection against overheating (to determine that, we used the ThrottleWatch utility). Therefore, we can't recommend the "boxed" and ThermalTake Jungle525 AE coolers for use. Nor we recommend to reduce the speed to the minimum on the Gigabyte 3D Cooler.

Gigabyte G-Power runs quietly and demonstrates simply fantastic performance. Even at the maximum speed the noise of the cooler is tolerable enough and is about the same as that for 3D Cooler running at 3000 RPM.

Also note the low noise level for coolers like Scythe Kamakiri and Igloo 5070 Light. If the user is not ambitious about overclocking the processor, all these three coolers can be safely recommended for purchase. But if the user has a rotational speed regulator, then instead of the Light version I would recommend the "generic" model of series Igloo 5070. As regards the model Igloo 5070 PWM, much will depend on how well is the implementation of the onboard system that observes the dependence of the cooler's rotational speed on the processor's temperature. Remember that this cooler offers a 4-pin power connector, and all the speed controllers in this case are useless.

While Scythe Kamakiri demonstrated good results (and we recommended it for purchase), this can't be said about the other two coolers by this company. Neither Kamaboko nor Samurai models coped with cooling the test processor, which resulted in switching on the Throttling. This situation is aggravated by the absolutely inconvenient (and laborious) procedure of installation.

By the way, a word on the ease of installation. The absolute leader in this field is the Gigabyte cooler (that holds true for coolers of series Gigabyte 3D Cooler and Gigabyte Rocket). The fastener is so simple and convenient that we have permanently used the G-Power cooler from the very first day it arrived at our test lab. But the "boxed" coolers cause nothing but annoyance. That applies first to the Jungle525 cooler.

As regards coolers of series Igloo 5070 and 5050, the procedure of their installation is rather simple. But we have to admit one more shortcoming: the gluing layer on the enforcement plate is very sticky, so you can glue the plate only once (or twice, at best). Besides, the residues of the glue spoil the look of the motherboard, which has a negative effect in case of a guarantee repair.

Now a couple of words on the ThermalTake product. As regards the Jungle525 cooler, I note that it is not enough replicate the design of the "boxed" cooler and increase the size of the radiator and the fan. The gained 2 C advantage does not make up for the difference between the "shareware" boxed cooler and the ThermalTake cooler.

As regards the retail price, we see that all the products are novelties, and number of bids is not very high. Anyway, on the PriceWatch.com web site there is Gigabyte G-Power at 40$, while on the Russian price.ru there are offerings of Kamaboko and Kamakiri coolers at 35$ and 54$, respectively. As a result, at the "price/efficiency" ratio the cooler by Gigabyte looks beyond any competition (even if its price in the Russian retail chain rises to 50$).

Summing it all up, we can call the Gigabyte G-Power cooler as the best which has ever been to our test lab. So we can easily forget any 3D Cooler's and turn solely to G-Power. As regards competition versus Zalman 7700Cu, at that the G-Power proves a favorite since at the minimum speed it doesn't run louder than the Korean cooler! Somehow or other, the response from Zalman is at hand, and at Computex the company demonstrated the CNPS9500 cooler in whose design heat pipes were used.

Coolers for Intel LGA775 processorsDate: 06/07/2005By: ; |

|

|||||